Home > How Humidity Affects Floor Finish

How Humidity Affects Floor Finish

With summer in full swing across most of the country, the potentially higher humidity levels are something to be aware of when applying floor finish. High humidity can directly affect the drying time and overall appearance of the finish on a floor.

Floor finishes contain many independent ingredients such as water, polymer, resin, wax, plasticizers, coalescing agents and defoamers that, when combined, form a stable liquid emulsion. Once applied to a floor, most of the ingredients evaporate. What doesn’t evaporate (and is left on the floor) is the non-volatile matter (NVM) or “solids” portion of the finish (polymer, resin, wax and plasticizers).

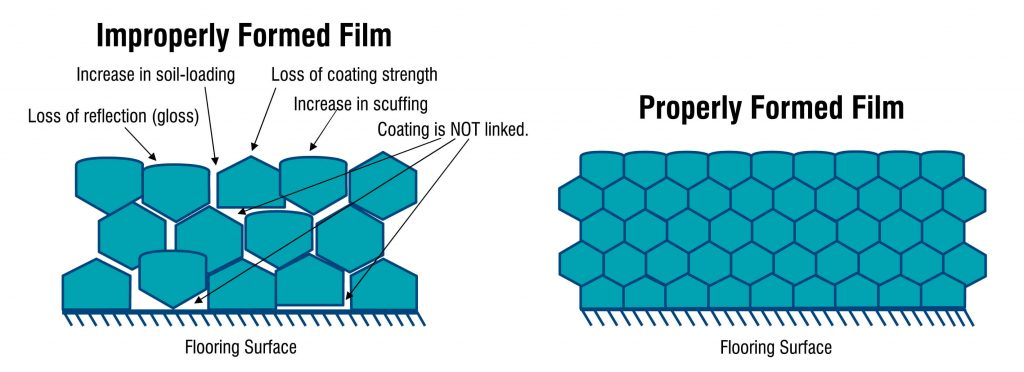

For best results, this evaporation process must be complete before another coat is applied. We can best illustrate this through the diagram below.

When a floor finish does not dry thoroughly and is re-coated, moisture gets trapped between the coats. A uniform, tightly coalesced film is never achieved. The results can be graying floors (soil penetration), excessive black marking and scuffing, sticking furniture and difficulty burnishing (powdering).

Humidity affects dry time in a profound manner. Remember, a lot of water must evaporate for a coat of finish to dry. High humidity means that the air is saturated with water. This, in turn, means that the water in the floor finish has nowhere to evaporate. Dry time for finishes that normally takes 30 minutes can take three or more hours. This is why we always recommend applying finish on cooler, less humid days or with the air-conditioning on. During very high humidity, it’s best to keep finish application on the low side of the recommended coverage rate.